The purpose of this technical position statement is to provide a general overview about the occurrences of copper, its economic uses, and its importance as a critical mineral. Through this discussion, SME presents information to inform meaningful dialogue about copper, which is an essential mineral in our economy, the energy transition, and national defense. Technical references regarding economic impacts of copper are noted at the end of this technical position statement.

Issue

Copper demand is expected to increase significantly due to its use in the technologies required for current and future electrical applications, alternative energy sources (e.g., wind, solar, geothermal), electronics for consumers, national defense and strengthening the power grid. Additionally, copper is increasingly recognized for its antimicrobial properties that are useful in preventing spread of viruses. Currently, there is not enough copper produced globally to meet projected future demand..

Background

Many historians consider copper as the first metal used by humans. The earliest documented use of copper was a pendant discovered in today’s northern Iraq, which dates approximately to 8,700 BCE (Before Common Era)1. Copper was also used as coin in Egypt as early as 3,400 BCE. The earliest copper refining was by charcoal reduction of carbonate ores, around 5000 BC2. In 3,000 BCE, copper was alloyed with tin to form bronze (12% tin and 88% copper), which was harder and stronger than tin or copper alone and began what is known widely as the Bronze Age. Zinc was later alloyed with copper to form brass (67% copper and 33% zinc). The word copper is derived from aes cyprium and kyprios, for the island of Cyprus, where Romans produced some of the earliest copper specimens.

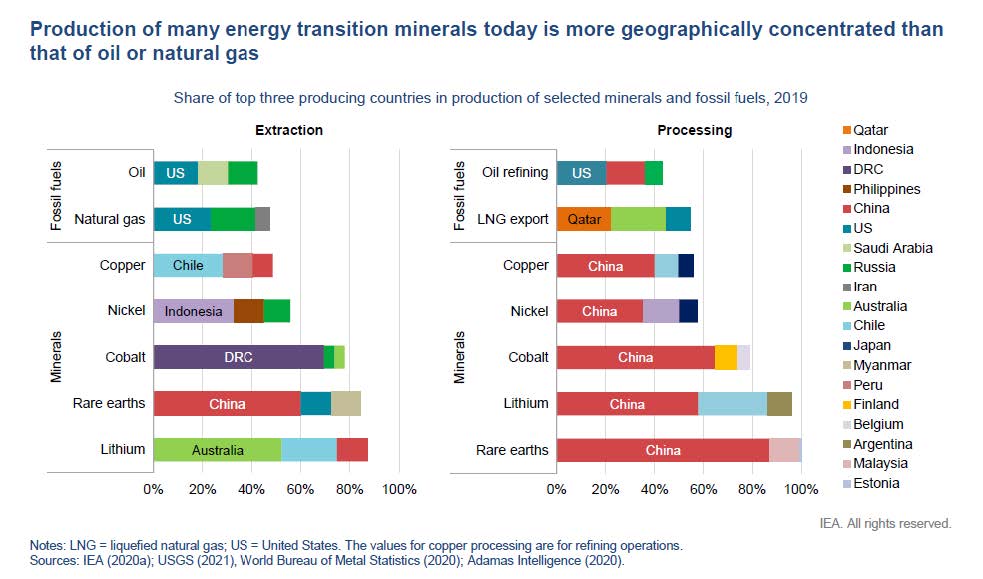

The Energy Act of 2020 defines a “critical material” as any non-fuel mineral, element, substance, or material that the Secretary of Energy determines: (i) has a high risk of supply chain disruption; (ii) serves an essential function in one or more energy technologies, including technologies that produce, transmit, store, and conserve energy; or (iii) as a critical mineral, as defined by the United States Geological Survey (USGS).3 The USGS defines a "critical mineral" as a mineral that: (i) is a non-fuel mineral or mineral material essential to the economic and national security of the United States; (ii) the supply chain of which is vulnerable to disruption; and (iii) serves an essential function in the manufacturing of a product, the absence of which would have significant consequences for our economy or our national security.3 Critical minerals are mostly produced in other countries, with generally greater than 50% of the domestic supply imported into the US. In 2019, the USGS established the first list of critical minerals, later revised in 2022, with further revisions expected in the future. Copper was not included in the revised list as the US imports approximately 46% for current use from other countries where trade agreements are in place and the supply of copper was not considered vulnerable to disruption. However, the US Department of Energy (DOE) recognized the need for additional copper supplies in order to transition to non-carbon energy sources and included copper as a critical material in 2023.4

Uses and Production

Copper is an excellent conductor of electricity and heat. Copper can be easily molded into wires, sheets, rods, or other forms to be used in numerous applications. Copper can be recycled; however, recycling alone cannot meet the current demand. In 2023, the relative percentages of copper and copper alloy products were used as follows: building construction, 45%; electrical and electronic products, 22%; transportation equipment, 16%; consumer and general products, 10%; and industrial machinery and equipment, 7%.5

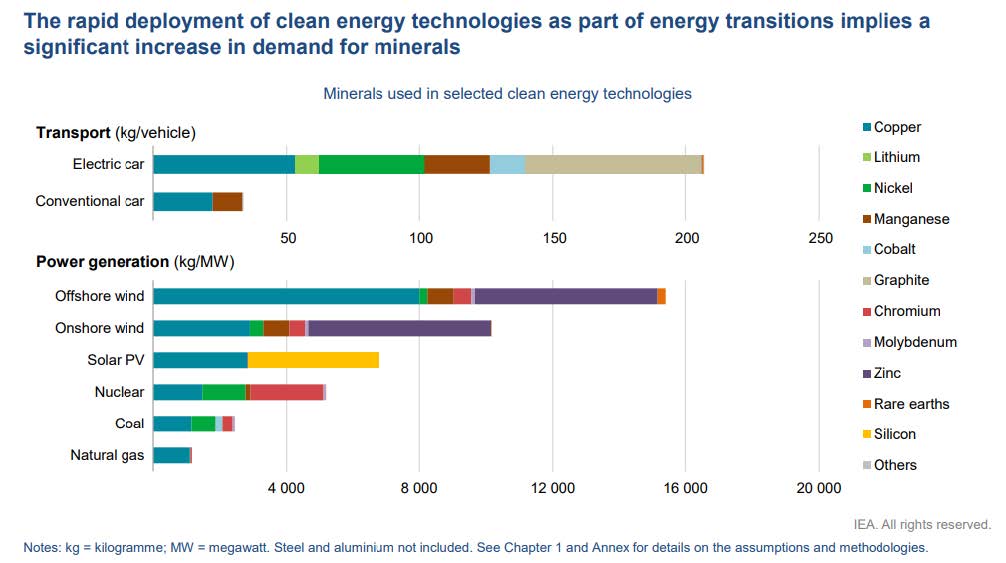

Clean energy technologies (e.g., wind and solar) and storage batteries require copper and other critical minerals and materials, and an increase in their demand will substantially increase the need for copper. For example, a 3-megawatt (MW) wind turbine contains 4.7 short tons of copper, used in the cables, wires, turbines, and transformers; and solar energy farms require 5.5 short tons of copper per MW produced, used in heat exchangers, wiring, and cables6.

Copper is also used in cables, wires, and switches used for energy storage devices and electricity transmission. A hybrid car requires 88-pounds (lbs) of copper and a fully electric car requires 183 lbs of copper, compared to 48 lbs of copper required for a typical internal combustion engine car. Charging stations ranging from 3.3- to 200-kilowatts (kW) for electric vehicles require 2- to 17-lbs of copper.6 Lead water pipes are currently being replaced with copper pipes in the US, which also increases the overall demand.

In 2023, global copper mine production was estimated as 22 million metric tons and refinery production was estimated as 27 million metric tons.5 Global copper reserves were also estimated in 2023 as 1 billion metric tons.5

U.S. copper production has increased steadily over the past several years. Copper was recovered or processed at 25 US mines, 17 of which accounted for more than 99% of U.S copper production. U.S. copper was processed using 2 primary smelters, 2 electrolytic refineries, and 14 electrowinning facilities located in the U.S. A new refinery in Kentucky opened in 2023 and three additional domestic facilities are expected to start within the next few years.5

Copper as a critical mineral

RISK OF SUPPLY DISRUPTION

Current copper mines are running out of ore, and grades and tonnages are decreasing rapidly. Globally, all mines can be subject to temporary closure due to a number of factors including weather, unexpected maintenance issues, and labor disputes. The opening of several large copper mines (e.g., Resolution, AZ; Rosemont, AZ; Pumpkin Hollow, NV; Pebble, AK; Twin Metals, MN; NorthMet/New Range, MN; Copper Flat, NM) continue to be delayed by technical, regulatory, financial, political, and social issues. The Biden administration recently put two very large domestic copper deposits, Twin Metals and Pebble, off limits to mining. Without these mines, the short-term supply of copper may be inadequate and subsequently disrupted.

TRADE EXPOSURE

In 2023, the US contributed to 5% of the global copper production.5 Copper is dominantly produced from mines in Chile (23% of global production), Peru (12%), Congo (11%), China (8%) and others.5 However, most of the global refinery production of copper is from China (44%), Chile (7%), and Japan (5%).5 Peru has been in political unrest recently, which may adversely affect the supply of copper from that country. Globally, labor disputes are common and can also adversely affect the copper supply chain.

CRITCAL MINERALS FOUND IN COPPER DEPOSITS

In addition to copper being a critical material, many critical minerals are produced as by-products from copper production including tellurium, arsenic, antimony, gallium, indium, cobalt, platinum group metals, and bismuth.7,8 Tellurium is used in the production of cadmium telluride, which can then be used in thin-film solar cells, and bismuth telluride, which can then be used in thermoelectric devices for cooling and energy generation. Arsenic has various uses including strengthening the grids in lead-acid storage batteries, antifriction additive for bearings, and to produce gallium-arsenide semiconductors for telecommunications, solar cells, and space applications. Antimony is used to manufacture munitions and other defense applications, as an oxide in flame retardants, some semiconductor devices, and to strengthen lead alloys. Bismuth is mainly used for chemicals in cosmetics, industrial, and pharmaceutical applications. Other critical minerals have the potential to be produced as by-products from future copper deposits, such as rare earth elements.7,8

Further research is needed to efficiently identify new copper resources. Research is needed to understand where critical minerals are found within copper deposits and how to economically recover these valuable commodities. Research into development of technologies that enable cleaner, more efficient, and lower-cost extraction and refining of copper is also needed. As we mine copper deposits, we need to recover as much of the target metals as possible from all stages of the mining and processing steps.

SME Statement of Technical Position

- Copper is essential to the U.S. economy and defense and should be considered a critical mineral by the USGS.

- Copper production will need to increase in order to meet projected future demand.

- Other critical minerals that are found in copper deposits must be identified and recovered.

- More research is needed to identify new copper resources and potential occurrence of critical minerals in these deposits, and to provide more efficient processing and recovery of copper and critical minerals.

- The US has both copper deposits and a rigorous regulatory structure to enable the responsible and safe extraction of domestic copper.

References

1Copper Development Association Inc., 2007, Discover copper online; From copper to bronze conquest: From Copper to Bronze to Conquest

2Butts, A. and Schlechten, A.W., 2024, Copper processing: Britannica, Copper processing - Refining, Alloying, Extraction | Britannica

3Fortier, S.M., Nassar, N.T., Lederer, G.W., Brainard, J., Gambogi, J., and McCullough, E.A., 2018, Draft Critical Mineral List - Summary of Methodology and Background Information - U.S. Geological Survey Technical Input Document in Response to Secretarial Order No. 3359: U.S. Geological Survey Open-File Report 2018-1021, 15 p., https://pubs.usgs.gov/of/2018/1021/ofr20181021.pdf (accessed January 24, 2024).

4US adds copper to critical raw materials list (mining-technology.com)

5U.S. Geological Survey. Mineral Commodity Summaries, 2024, Mineral Commodity Summaries 2024 (usgs.gov).

6The Role of Critical Minerals in Clean Energy Transitions (iea.blob.core.windows.net)

7Granitto, M., Emsbo, P., Hofstra, A.H., Orkild-Norton, A.R., Bennett, M.M., Azain, J.S., Koenig, A.E., and Karl, N.A., 2020, Global Geochemical Database for Critical Minerals in Archived Mine Samples: U.S. Geological Survey data release, https://doi.org/10.5066/P9Z3XL6D.

8John, D. A., & Taylor, R. D. (2016). By products of Porphyry Copper and Molybdenum Deposits. Economic Geology, 137-164.

Download PDF